The automotive industry is adopting Virtual Estimating Collision (VEC) tools to digitize damage assessment and repair planning, replacing physical inspections with advanced imaging, 3D modeling, and AI. These solutions enable remote vehicle assessments, accurate repair estimates, and significant productivity gains, ultimately enhancing customer experience through timely and precise service.

In today’s digital era, managing repair backlogs efficiently is paramount for automotive workshops. Unlocking efficiency with Virtual Estimating Collision (VEC) tools offers a transformative solution. This innovative technology streamlines the initial assessment process, enabling quicker and more accurate damage evaluations. By leveraging VEC, workshops can make data-driven decisions, prioritize tasks, and optimize resource allocation. This article explores how digital methods in collision estimation revolutionise repair management, providing insights into increasing productivity and customer satisfaction.

- Unlocking Efficiency: Virtual Tools for Collision Estimation

- Streamlining Repair: Digital Methods and Their Impact

- Data-Driven Decisions: Managing Backlogs Effectively

Unlocking Efficiency: Virtual Tools for Collision Estimation

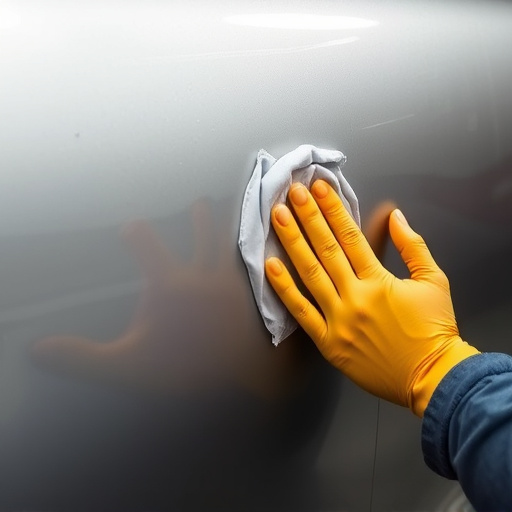

The world of automotive repair services is undergoing a digital transformation with the advent of virtual estimating collision tools. These innovative solutions are revolutionizing how damage assessment and repair planning are conducted, particularly in managing backlogs efficiently. Traditional methods often relied on physical inspections, which could be time-consuming and labor-intensive, especially for complex car dent removals.

Virtual estimating collision platforms offer a sophisticated approach by utilizing advanced imaging, 3D modeling, and AI algorithms to create digital representations of vehicle damage. This technology allows estimators to remotely assess vehicles, compare them against pre-existing databases, and generate accurate repair estimates. By streamlining the initial assessment process, these virtual tools significantly enhance productivity in car repair services while ensuring precise and timely estimations for customers.

Streamlining Repair: Digital Methods and Their Impact

In today’s digital era, the automotive industry has witnessed a significant transformation in how repairs are handled, particularly through the adoption of virtual estimating collision technologies. These innovative digital methods offer a streamlined approach to managing auto body repair processes within car repair shops and collision centers. By leveraging advanced software tools, technicians can now virtually assess and estimate collision damage with unprecedented precision.

This shift from traditional, time-consuming manual inspections has revolutionized auto body repair. Virtual estimating collision platforms provide real-time data and detailed imaging, enabling quicker decision-making and more accurate cost projections. As a result, collision damage repair processes become more efficient, reducing wait times for customers and optimizing workflow management within the car repair shop. This technology is a game-changer in ensuring that repair backlogs are managed effectively, fostering customer satisfaction, and enhancing overall operational productivity.

Data-Driven Decisions: Managing Backlogs Effectively

In today’s digital era, embracing innovative technologies like virtual estimating collision (VEC) is pivotal for effectively managing repair backlogs at automotive service centers. VEC leverages advanced software and 3D imaging to accurately assess vehicle damage remotely, enabling data-driven decisions that streamline the collision repair process. This technology revolutionizes traditional on-site inspections by providing detailed digital records of car dent repairs, mercedes benz collision repair, and other damage types.

By relying on virtual estimating collision, repair facilities can significantly enhance operational efficiency. Data-driven insights enable them to allocate resources optimally, prioritize work orders based on urgency and severity, and predict turnaround times more accurately. This proactive approach not only minimizes customer wait times but also ensures that even complex cases are tackled systematically. As a result, collision repair processes become smoother, leading to higher customer satisfaction levels across the board.

Virtual estimating collision technologies are transforming how repair backlogs are managed, offering significant advantages over traditional methods. By leveraging digital tools, auto body shops can streamline their processes, enhance efficiency, and make data-driven decisions. This not only reduces overall costs but also improves customer satisfaction through faster turnaround times. Embracing virtual estimating collision is a game-changer for managing repair backlogs in the modern automotive industry.