Virtual Estimating Collision (VEC) is a cutting-edge digital tool that revolutionizes project management by predicting and reducing delays in complex projects like auto bodywork and car repair services. Leveraging advanced technologies, VEC simulates real-world scenarios, considering variables like resource availability, weather, and unexpected repairs for more accurate schedules and efficient resource allocation. This innovation streamlines processes, enables fast data capture, precise damage assessments, and remote approval, enhancing efficiency, customer satisfaction, and turnaround times for both simple repairs and complex vehicle restorations.

In today’s fast-paced project management landscape, minimizing scheduling delays is paramount. Enter virtual estimating collision—a novel approach that leverages technology to optimize task allocation and resource utilization. This cutting-edge method identifies potential bottlenecks and conflicts before they occur, ensuring projects stay on track. By understanding and implementing strategies around virtual estimating collision, teams can eliminate delays, enhance efficiency, and deliver projects with greater precision and speed.

- Understanding Virtual Estimating Collision: A Novel Approach to Project Management

- The Impact on Scheduling: Eliminating Delays and Enhancing Efficiency

- Implementation Strategies: Adopting Virtual Techniques for Smooth Operations

Understanding Virtual Estimating Collision: A Novel Approach to Project Management

Virtual Estimating Collision (VEC) is a groundbreaking approach to project management that leverages advanced digital technologies to anticipate and mitigate potential delays in complex projects. Unlike traditional estimating methods, VEC simulates real-world scenarios by factoring in various variables that could disrupt timelines, such as resource availability, weather conditions, and unexpected repairs. This innovative technique enables project managers to create more accurate schedules and allocate resources efficiently, thereby minimizing the risk of scheduling delays.

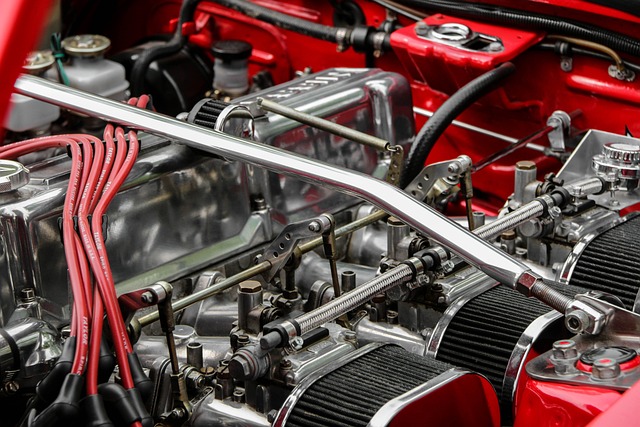

By applying VEC, professionals in the auto bodywork and car repair services industries can streamline their operations significantly. For instance, virtual collision estimators can predict the time required for dent removal or other repairs with remarkable precision, ensuring that subsequent tasks are scheduled accordingly. This proactive approach not only enhances overall project efficiency but also boosts client satisfaction by delivering results on time, every time.

The Impact on Scheduling: Eliminating Delays and Enhancing Efficiency

The adoption of virtual estimating collision technologies has significantly revolutionized the way automotive repair and body shop services operate. By enabling precise and efficient assessments of vehicle damage, this innovative approach eliminates many delays traditionally associated with manual inspection. In the past, evaluating a Mercedes-Benz repair or any complex vehicle restoration required significant time, often leading to longer scheduling times for customers.

Now, virtual collision estimating allows technicians to quickly capture detailed images and data from damaged vehicles, enabling accurate calculations of parts and labor costs. This digital transformation enhances overall efficiency, as estimators can review and approve repairs remotely, reducing the need for in-person meetings. Consequently, clients benefit from faster turnaround times, ensuring their vehicles are returned promptly, be it for a simple repair or a comprehensive body shop service.

Implementation Strategies: Adopting Virtual Techniques for Smooth Operations

Implementing virtual estimating collision techniques is a game-changer for many auto body repair shops, especially when aiming to streamline operations and avoid scheduling delays. By adopting these innovative methods, professionals in the industry can significantly enhance efficiency. One of the key strategies is leveraging digital tools for initial assessments; instead of relying solely on physical inspections, technicians can use 3D imaging and computer-aided design (CAD) software to virtually examine vehicles, identify damages, and create accurate repair estimates. This approach reduces the time spent on site, allowing for quicker turnaround times.

For instance, when dealing with a Mercedes Benz repair or vehicle dent repair, virtual estimating collision can capture intricate details of the damage, ensuring that no visible flaws are overlooked. Once the digital assessment is complete, the data can be fed into specialized software capable of generating precise cost calculations and part recommendations. This streamlined process not only improves productivity but also enhances customer satisfaction by providing transparent pricing and expediting service times, whether it’s for auto body repair or more specialized tasks.

Virtual Estimating Collision offers a revolutionary approach to project management, significantly reducing scheduling delays. By utilizing advanced techniques, this method enhances efficiency and streamlines operations. Implementing these virtual strategies ensures smooth project execution, allowing teams to meet deadlines with improved accuracy and productivity. This innovative practice is a game-changer in the industry, providing a reliable solution for effective project planning and delivery.